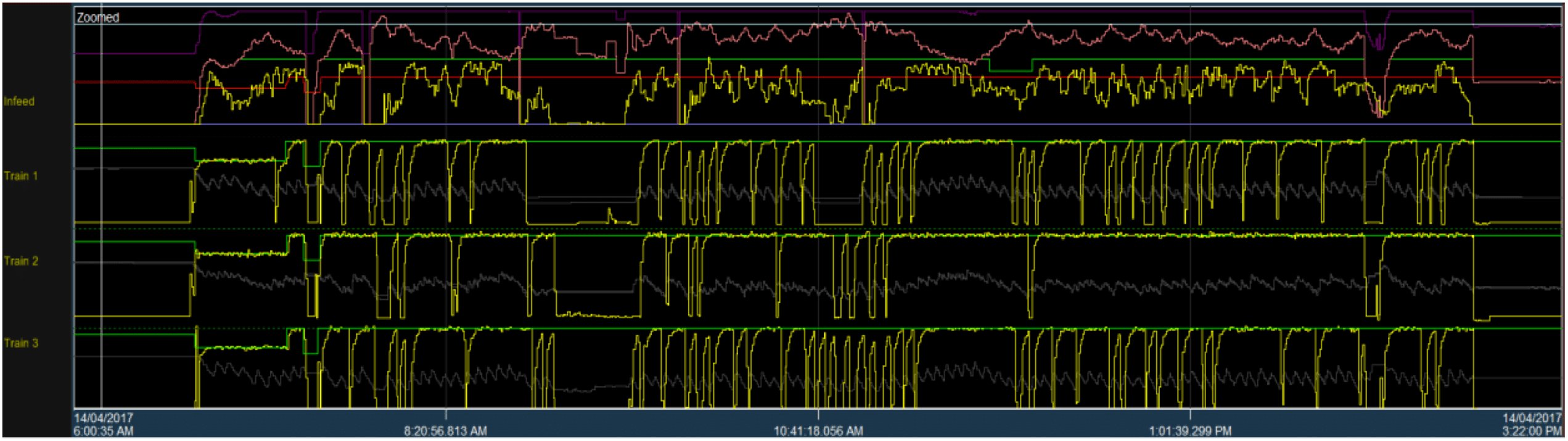

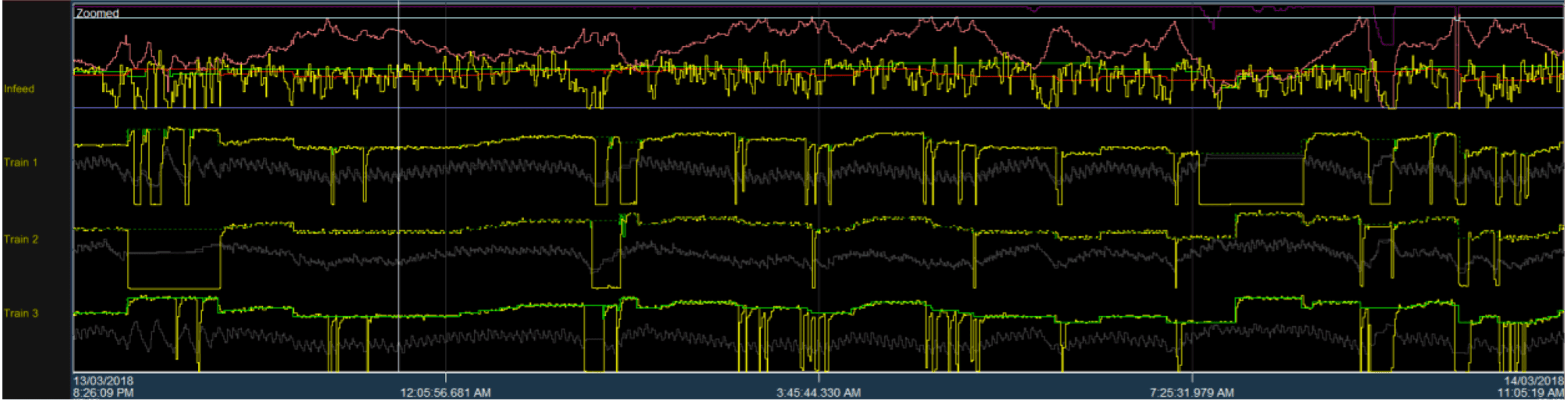

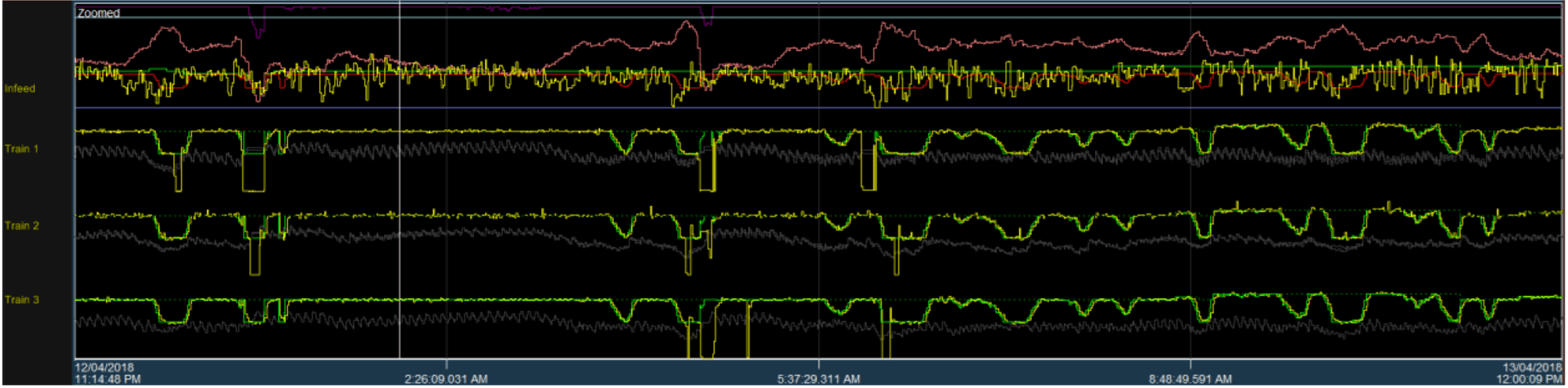

It was found that constant starting and stopping of feed to a scrubbing circuit was leading to higher product moisture and was propagating feed variability to other sections of the plant.

New control logic was needed around scrubbing feed to improve the ramping up and down of feed rates in response to changes in infeed to the plant. The goals of this control are to ensure maximum throughput of ore through the plant and to reduce the amount of bin emptying events. These two goals can be conflicting as avoiding emptying bins can constrain production and vice versa.

The first step in improving control was to work with control room operators to determine what set point changes could be made on the existing control system to handle feed variability. This was the quickest way to get results. This proved very successful and eliminated a lot of start/stop events. However, it did still require a lot of operator oversight and at times attention cannot be spared exclusively for this section of plant.

Control logic was then developed that was able to automatically measure when a slowdown was required. This reduced the emptying events in a way that would not impose an artificial restriction in scrubbing rates when the plant would be capable of running at higher rates.