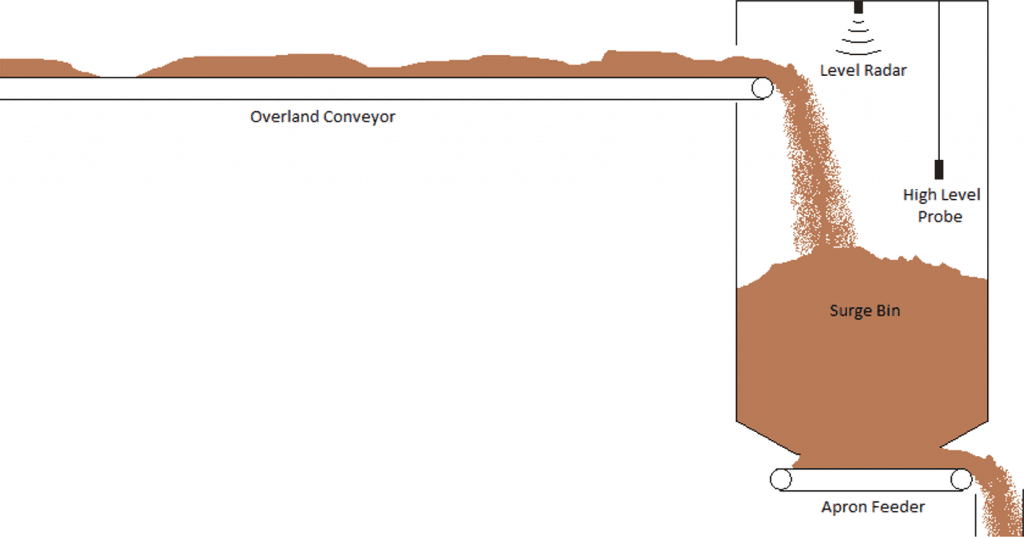

A new overland conveyor was added to the plant to reduce costs associated with transporting ore from more distant pits to the plant. To reduce project costs, a relatively small surge bin was used downstream of the overland conveyor. This meant when the plant’s demand for ore changed, the overland conveyor would very frequently be required to stop to avoid overfilling the surge bin.

The overland conveyor’s ability to run at variable speeds was used here for optimising the process. Feedback and feed forward controllers on the overland conveyor and the belt feeder under the surge bin were installed and tied in to the over-arching infeed control system. This allowed speed adjustments to be made on both the overland conveyor and apron feeder. This allowed more stable feed out of the bin and reduced complete starts and stops.