Shiploaders load ships in a pre-planned sequence into different hatches. This is done to ensure the ore load is added to the ship in a controlled manner to reduce stresses to the ship’s structure.

When a shiploader changes hatches, an ore gap needs to be planned to prevent spillage over the ship’s deck. These ore gaps, although very necessary, increase the time required to load a ship.

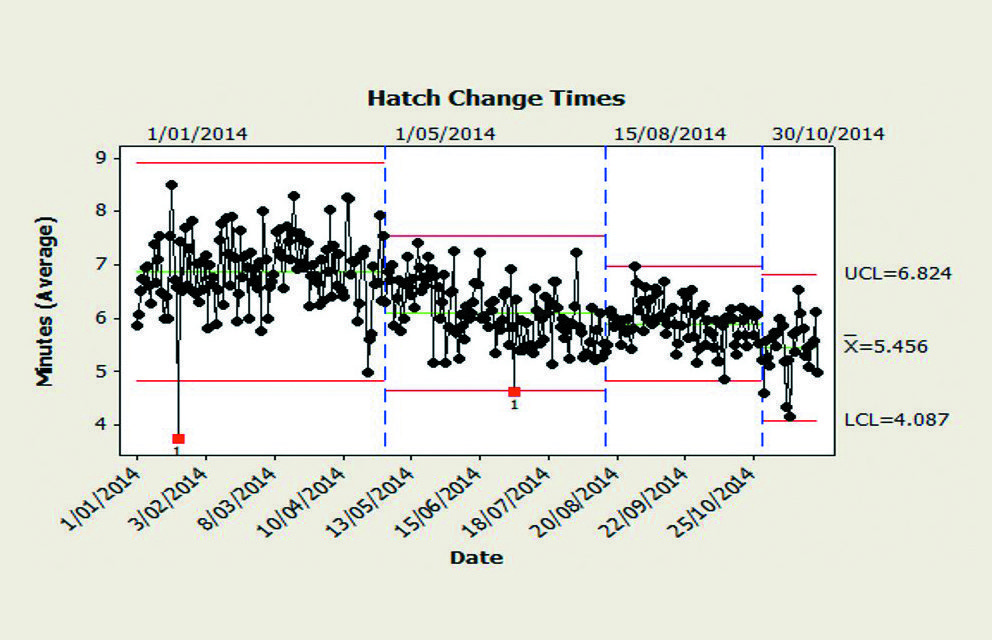

The PLC logic that controls the shiploader’s movements between hatches was optimised leading to a reduction in time required to change hatches along with smoother machine movements.